Introduction

In the HVAC trade, avoiding mistakes is just as important as doing the job right. Even seasoned technicians can run into problems that cause expensive callbacks, wasted hours, and lost profits. As a wholesale HVAC supplier, we’ve seen the patterns — and we know how the right materials and techniques can prevent them.

Here’s a technician-focused guide to help you avoid the top 10 HVAC installation mistakes so you can protect your time, reputation, and bottom line.

1. Skipping the System Sizing Step

Mistake: Installing without proper load calculations.

Why It Hurts: Leads to oversized/undersized systems, higher utility bills, and customer dissatisfaction.

Fix: Always perform Manual J load calculations before equipment recommendations.

2. Poor Refrigerant Line Handling

Mistake: Kinking, contamination, or poor insulation of refrigerant lines.

Why It Hurts: Causes compressor failure and reduced efficiency.

Fix: Use bending tools, insulate completely, and purge with nitrogen when brazing.

3. Ignoring Manufacturer Clearance Requirements

Mistake: Tight installations without proper airflow clearance.

Why It Hurts: Overheating, reduced performance, voided warranties.

Fix: Follow manufacturer manuals precisely for clearance specs.

4. Incorrect Thermostat Wiring

Mistake: Miswiring thermostats, especially for multi-stage or communicating systems.

Why It Hurts: System malfunctions and component damage.

Fix: Use proper 18-2 to 18-10 thermostat wire and double-check terminal assignments.

5. Forgetting to Change the Filter at Start-up

Mistake: Leaving a dirty or restrictive filter in during commissioning.

Why It Hurts: Immediate airflow restriction and reduced system life.

Fix: Replace with a clean filter and show the customer how to maintain it.

6. Skipping the Vacuum and Leak Test

Mistake: Charging without pulling a deep vacuum or leak testing.

Why It Hurts: Moisture and air in the system reduce performance and lifespan.

Fix: Use a micron gauge and confirm vacuum hold.

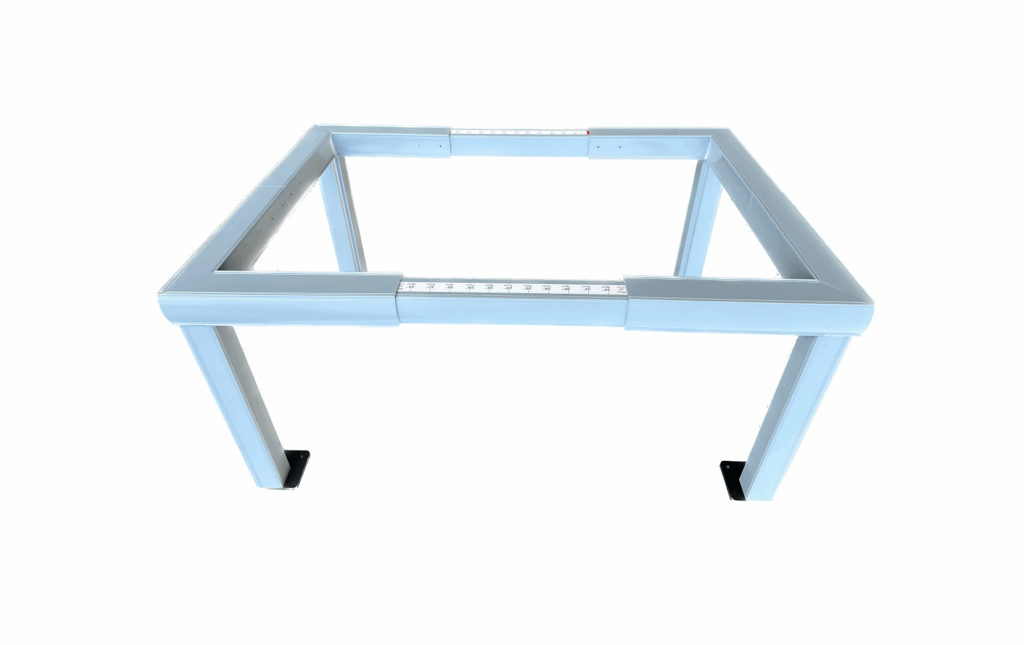

7. Not Leveling Outdoor Units

Mistake: Installing outdoor units on uneven surfaces.

Why It Hurts: Causes compressor wear and poor drainage.

Fix: Use an adjustable aluminum heat pump stand for a level, secure installation.

8. Using the Wrong Sealant

Mistake: Choosing generic or non-HVAC-rated sealants.

Why It Hurts: Leaks, water damage, and callbacks.

Fix: Use HVAC-grade silicone sealant matched to the application.

9. Overlooking Electrical Code Compliance

Mistake: Using non-compliant electrical materials.

Why It Hurts: Failed inspections, safety hazards.

Fix: Use CSA-approved 600V TC-ER wire for ductless and other relevant installs.

10. Not Registering Equipment Warranties

Mistake: Forgetting or delaying warranty registration.

Why It Hurts: Reduced coverage and higher liability.

Fix: Complete registration online immediately after installation.

Conclusion

Avoiding these common HVAC installation mistakes saves you time, prevents costly callbacks, and boosts customer satisfaction. At Future Supply, we stock everything you need — from CSA-approved wire to adjustable aluminum stands — so your installs are right the first time.